Modern technologies, progress and properly adjusted production processes. This is the secret of success that takes place in our production halls. Find out what we can produce and provide in our “technology park”.

An internal team of designers and programmers,

Utilizing SolidWorks for part and tool design,

Moldex3D for mold flow simulations,

SolidCAM software.

3-5 axis CNC milling (15 machines), max. part size 2600x1600x800mm,

6-axis CNC turning (2 stroke), max. part size D500x700mm,

High-speed CNC machine with graphite electrode.

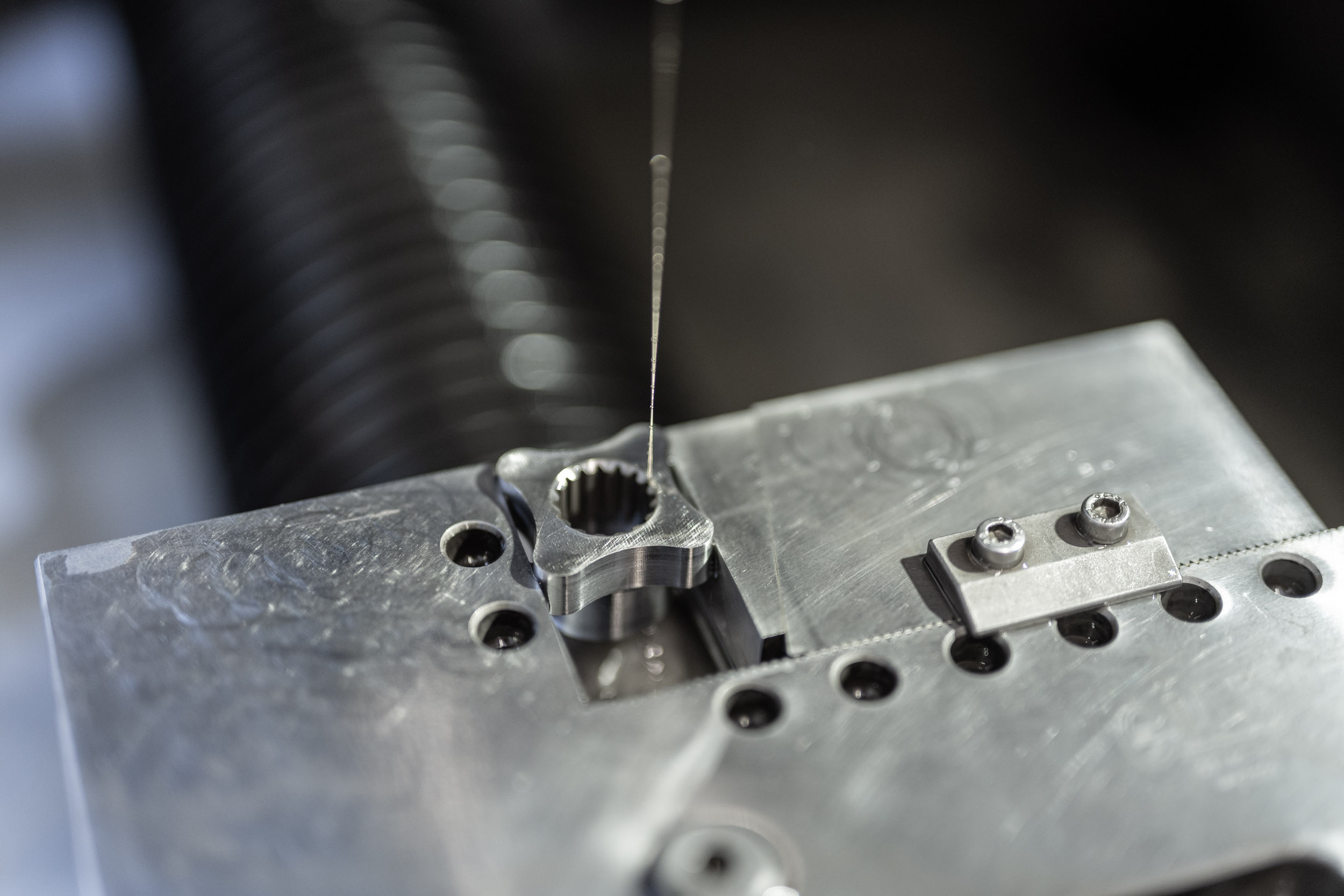

EDM cutting (2 Machines), max. part size 1000x550x310mm,

EDM die sinker (3 machines), max. part size 1600x800x600mm.

Surface grinding machines,

Rotary part grinding.

Capabilities for laser welding, marking, and engraving parts.

Machines up to 250t and maximum mold size 1.2×0.8m.

3D CMM machines (3 pieces), max. part size 1500x1000x800mm,

3D laser scanning (accuracy 0.008mm),

ISO 9001 and ISO 14001 certifications.

Quick repair and modification.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | CookieYes sets this cookie to store the user consent for the cookies in the category "Advertisement". |

| cookielawinfo-checkbox-analytics | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Analytics” category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by the GDPR Cookie Consent plugin to record the user consent for the cookies in the category “Functional”. |

| cookielawinfo-checkbox-necessary | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Necessary” category. |

| cookielawinfo-checkbox-others | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Others”. |

| cookielawinfo-checkbox-performance | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Performance”. |

| CookieLawInfoConsent | 1 year | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | The website's WordPress theme uses this cookie. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| wpEmojiSettingsSupports | session | WordPress sets this cookie when a user interacts with emojis on a WordPress site. It helps determine if the user's browser can display emojis properly. |

| Cookie | Duration | Description |

|---|---|---|

| wp-wpml_current_language | session | WordPress multilingual plugin sets this cookie to store the current language/language settings. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |