Based on orders, we manufacture parts for the automotive industry that differ from standard components used in car construction.

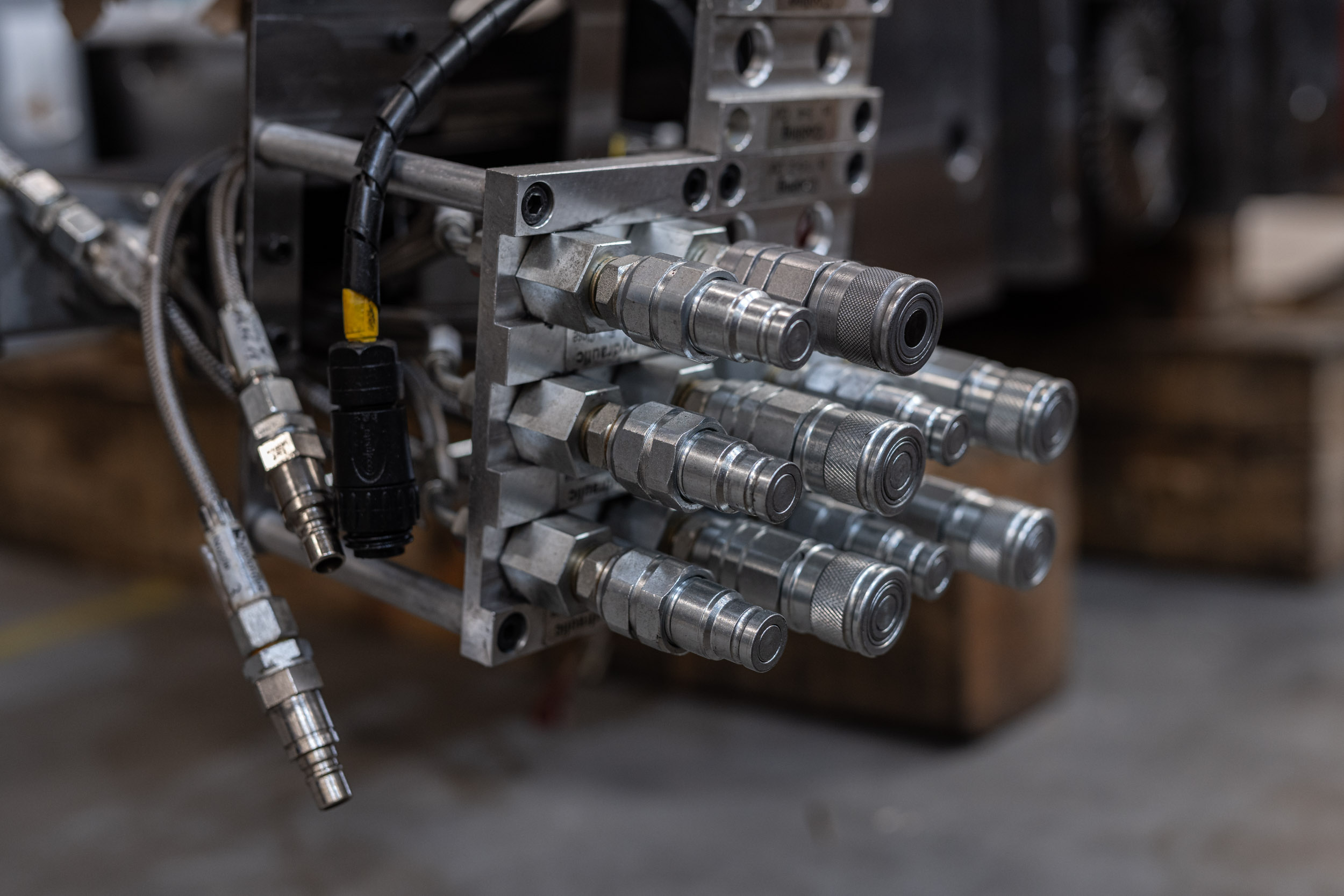

We can manufacture spare parts and components for molds from our and outside our production and ensure mold maintenance, thus keeping operations running with minimal impact on production.

In manufacturing engineering products, we rely on two decisive elements. Our highly specialized and modern technological equipment allows us to turn design into reality.

However, the ace up our sleeve is our team of experts within our CAM (Computer Aided Manufacturing) team—engineers, programmers, technicians, and specialists who can efficiently carry out the production from the client’s perspective. This group implements and executes technologies to automate and optimize production processes for a specific engineering product, minimizing costs and shortening the timeframe until final production.

The product is then verified in our internal measuring center, ensuring you receive a detailed report that verifies that it conforms to the documentation.

Within the manufacturing process, we also ensure the required modifications of the engineering product, which we can again provide within our technological range. Examples include surface treatment or the entire volume by hardening, various coatings, etc.

The product’s delivery continues beyond our cooperation. At R&D MOLD MACHINING, we can provide components and spare parts if needed.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | CookieYes sets this cookie to store the user consent for the cookies in the category "Advertisement". |

| cookielawinfo-checkbox-analytics | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Analytics” category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by the GDPR Cookie Consent plugin to record the user consent for the cookies in the category “Functional”. |

| cookielawinfo-checkbox-necessary | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Necessary” category. |

| cookielawinfo-checkbox-others | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Others”. |

| cookielawinfo-checkbox-performance | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Performance”. |

| CookieLawInfoConsent | 1 year | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | The website's WordPress theme uses this cookie. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| wpEmojiSettingsSupports | session | WordPress sets this cookie when a user interacts with emojis on a WordPress site. It helps determine if the user's browser can display emojis properly. |

| Cookie | Duration | Description |

|---|---|---|

| wp-wpml_current_language | session | WordPress multilingual plugin sets this cookie to store the current language/language settings. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |