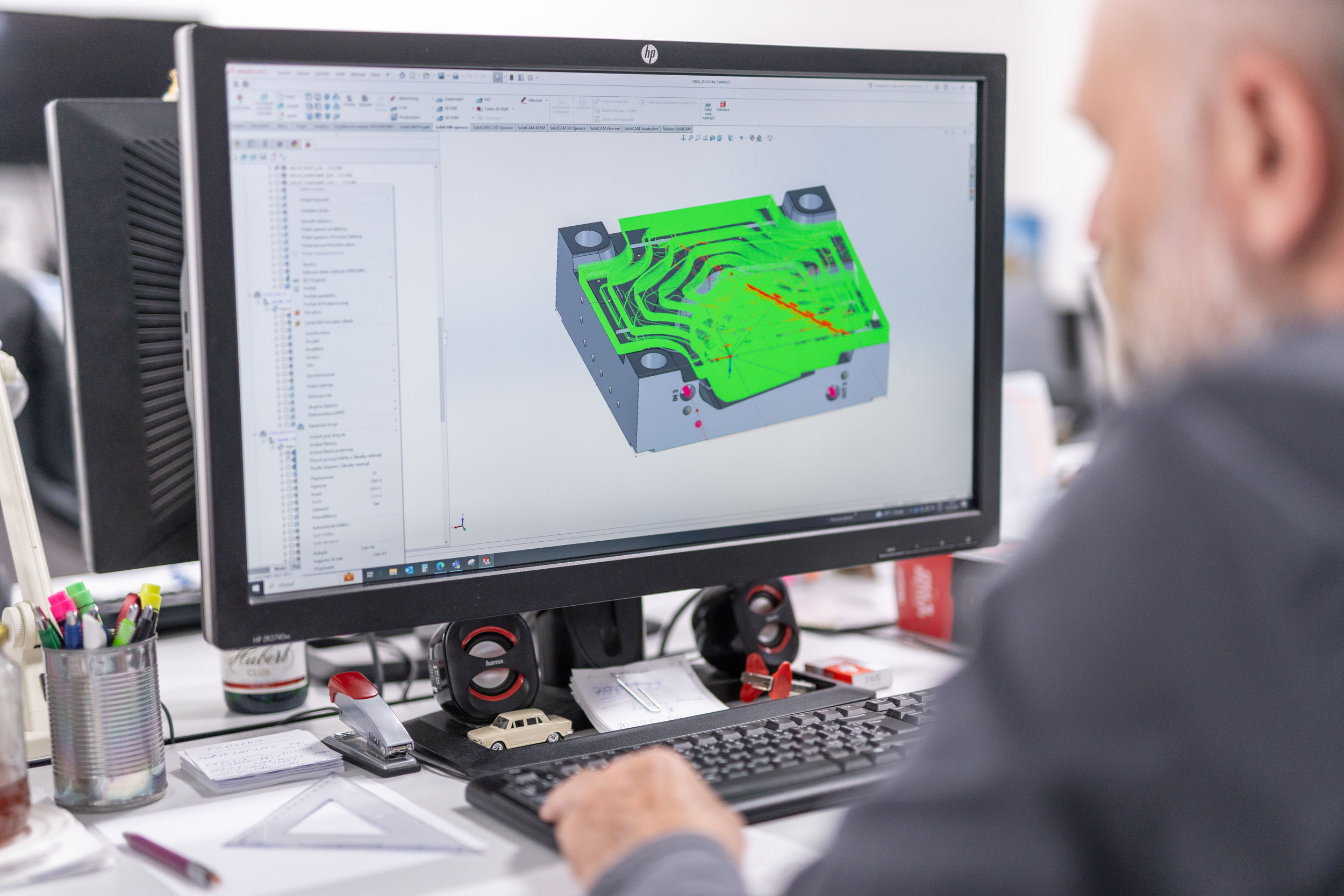

As part of our extensive engineering services related to mold, product design, and the actual part, we design and simulate the most efficient production method. Based on your documentation, we will create a mold model, including an analysis of its construction. As part of the engineering process, we consult the design to eliminate unexpected complications and ensure the outcome meets your expectations. With professional software and our engineers’ experience, we identify potential critical points during the mold design phase that could increase mold or part production costs later.

Based on the initial information and documentation, we gather all necessary data to ensure comprehensive steps for producing injection molds for plastics, carbon molds, or even unique products.

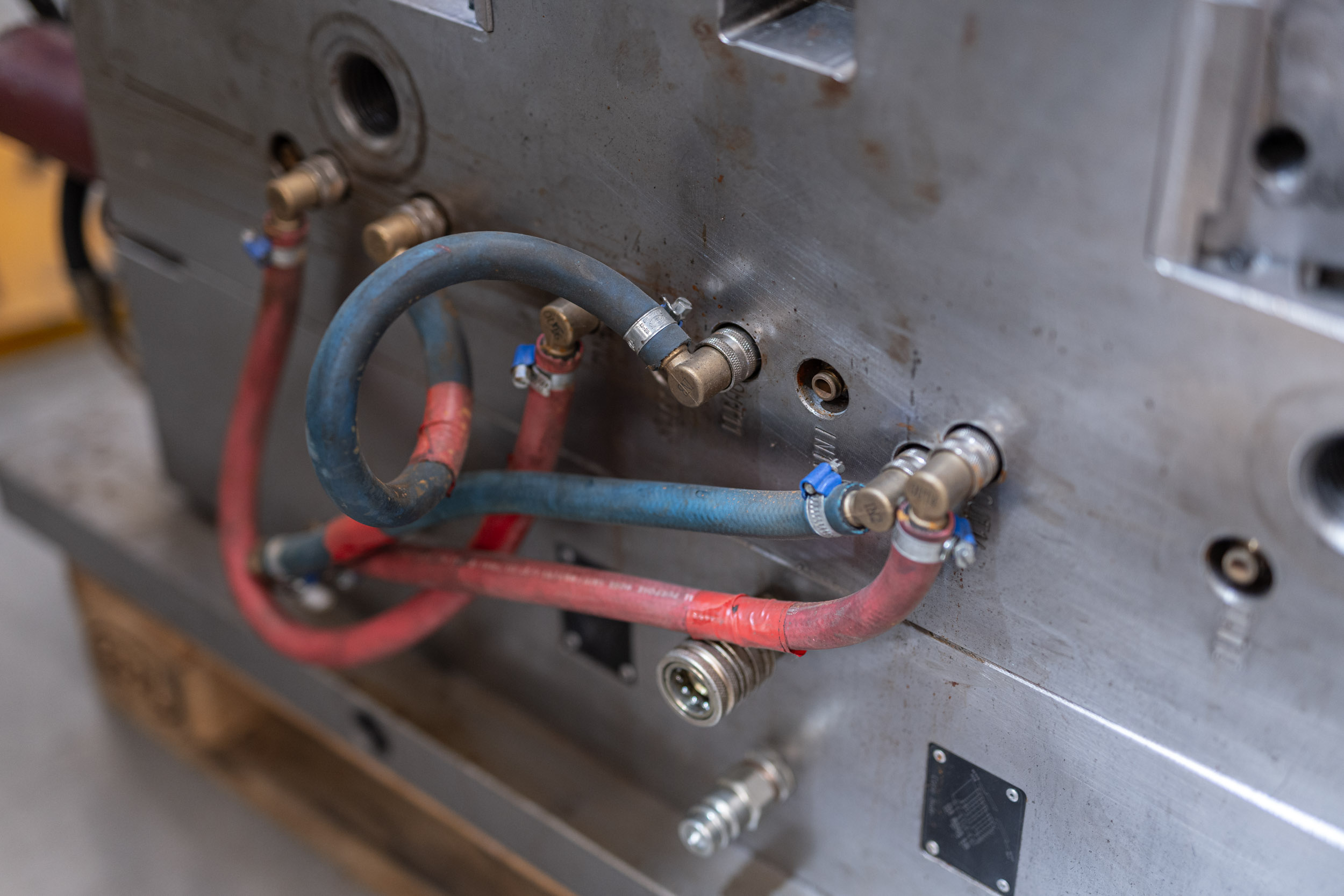

Engineers will use CAD systems to develop the mold’s structure and design. This process will determine the final geometry of the injection, composite, or prototype mold and include solutions for the injection system (for injection molds), cooling, and other essential details.

of products, as well as injection molds and carbon molds. The feasibility study helps us define whether a part is manufacturable and identifies the most optimal technologies for its production. This step in our engineering services can optimize the production design, saving time and costs associated with part production.

The feasibility of production includes a mold flow analysis. The process allows us to predict problems, minimize waste, and improve the efficiency of the entire process. It deals with the mold’s process feasibility, addressing injection, cooling, stresses, deformations, and production cycles.

Using a laser 3D scanner and CMM devices, part of our measuring laboratory, we convert an actual product, part, or component into a virtual form. We achieve the most detailed 3D model of the real object by converting the output from the laser scanner (so-called cloud of points) combined with proven approaches to reverse engineering and supported by CAD systems in the hands of our experts.

The process allows us to ensure the production of missing parts or components or even replacement parts despite the lack of project or production documentation.

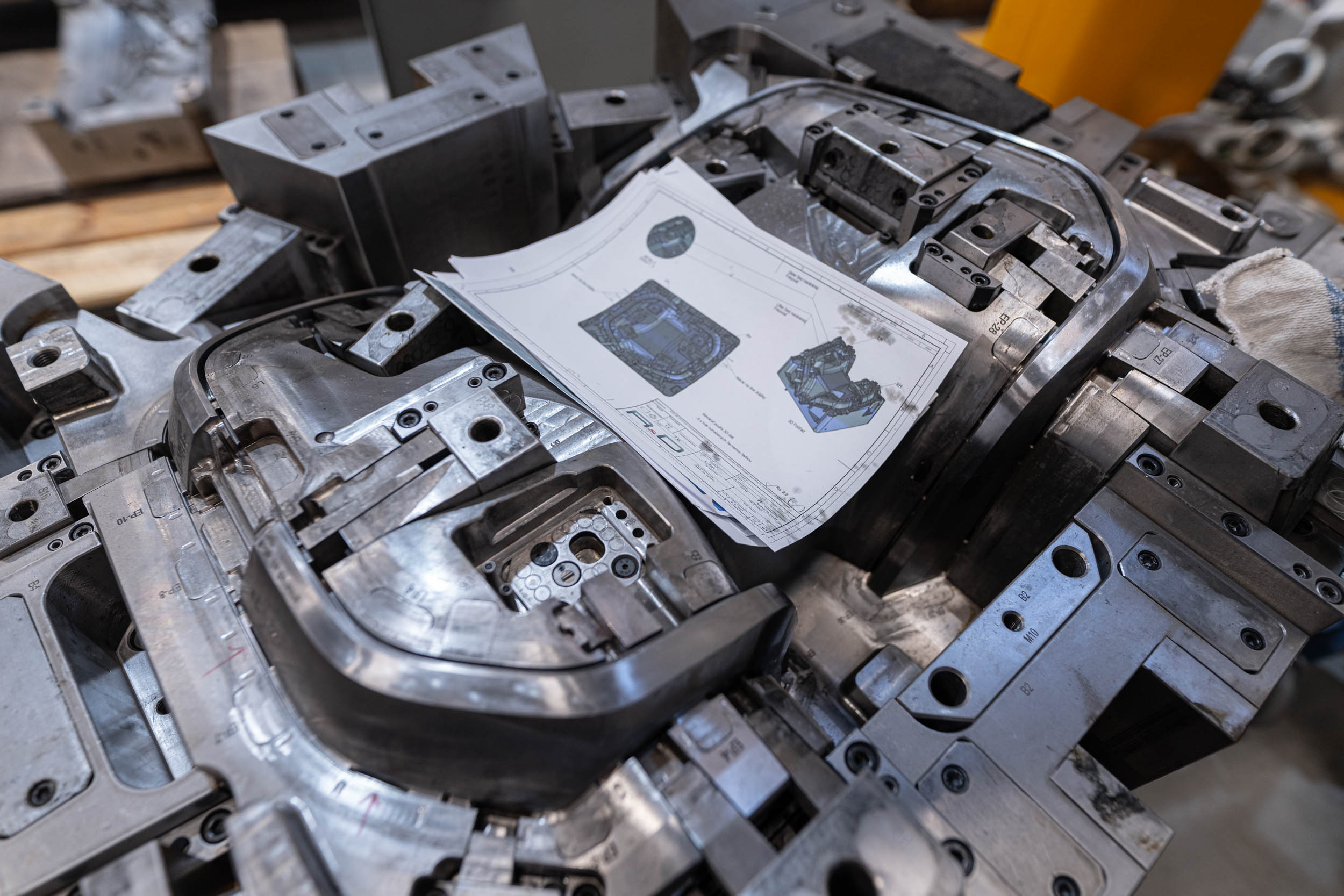

We can ensure the production of prototype molds according to your requirements, for example, small-scale production, intermediate part production, pilot trial mold production, or verification of product parameters.

Our specialty is producing molds for composites. In a comprehensive range, we can cover the related services for carbon part mold production, sample creation from the mold, and even final production in cooperation with the R&D COMPOSITE division.

We provide production and related services for a wide range of products. Examples include tools, components and parts, devices, spare parts, robotics, or parts for the automotive and other industries.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | CookieYes sets this cookie to store the user consent for the cookies in the category "Advertisement". |

| cookielawinfo-checkbox-analytics | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Analytics” category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by the GDPR Cookie Consent plugin to record the user consent for the cookies in the category “Functional”. |

| cookielawinfo-checkbox-necessary | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Necessary” category. |

| cookielawinfo-checkbox-others | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Others”. |

| cookielawinfo-checkbox-performance | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Performance”. |

| CookieLawInfoConsent | 1 year | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | The website's WordPress theme uses this cookie. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| wpEmojiSettingsSupports | session | WordPress sets this cookie when a user interacts with emojis on a WordPress site. It helps determine if the user's browser can display emojis properly. |

| Cookie | Duration | Description |

|---|---|---|

| wp-wpml_current_language | session | WordPress multilingual plugin sets this cookie to store the current language/language settings. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |