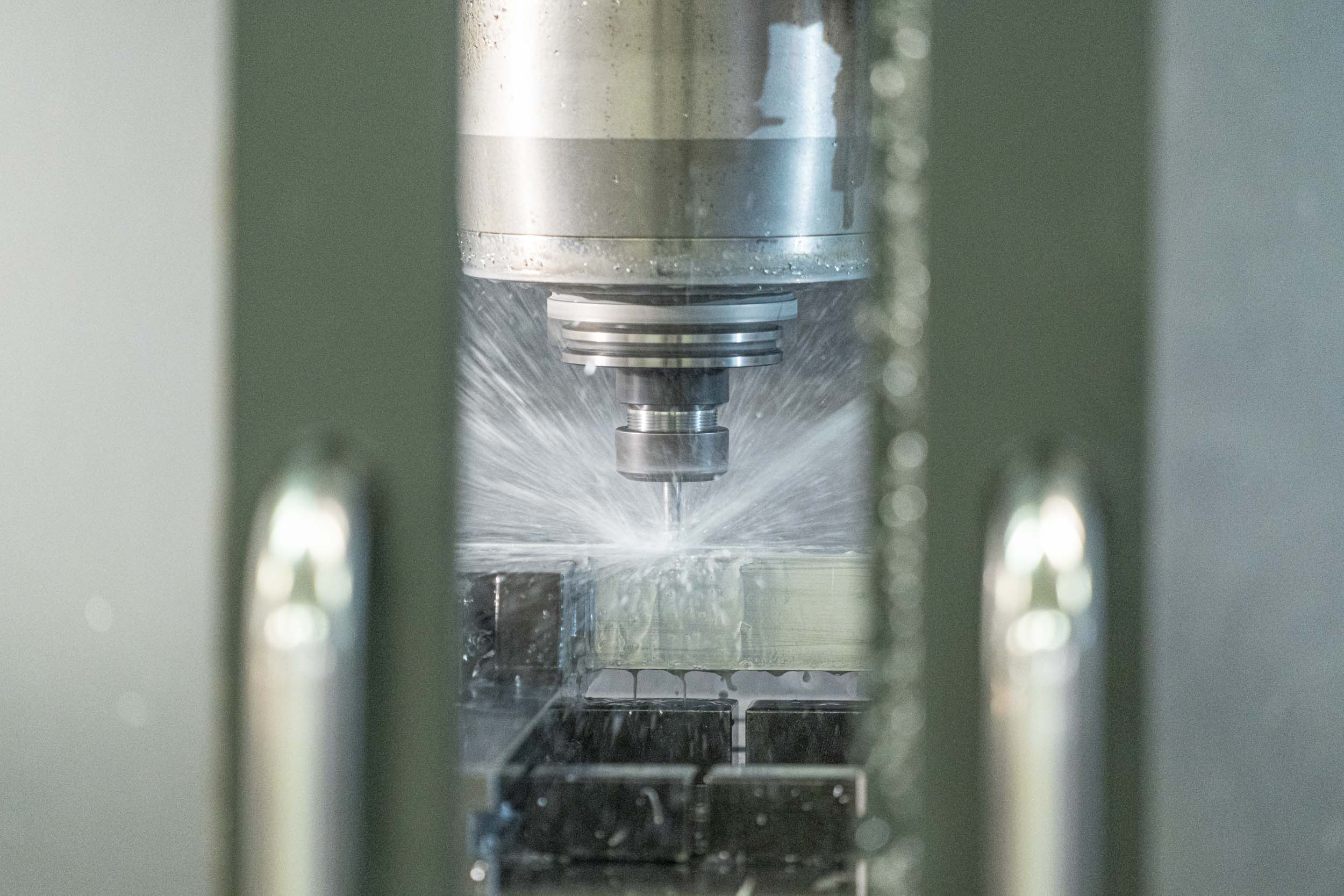

Measuring fixtures are standard in the automotive industry. They offer an alternative to measuring, testing, and evaluating plastic parts produced by injection molding and composites. Instead of technologically, personnel, and financially demanding procedures in specialized measuring laboratories (with CMM technology), a measuring fixture evaluates critical parameters essential for product quality verification, allowing production to progress confidently.

Fixtures for particular purposes require specific technical properties, parameters, or functions. They can meet specific demands necessary for use in areas where standard equipment is not applicable. We can produce vibration fixtures, light fixtures, laboratory equipment, fixtures for medical, military, and aerospace purposes, and more.

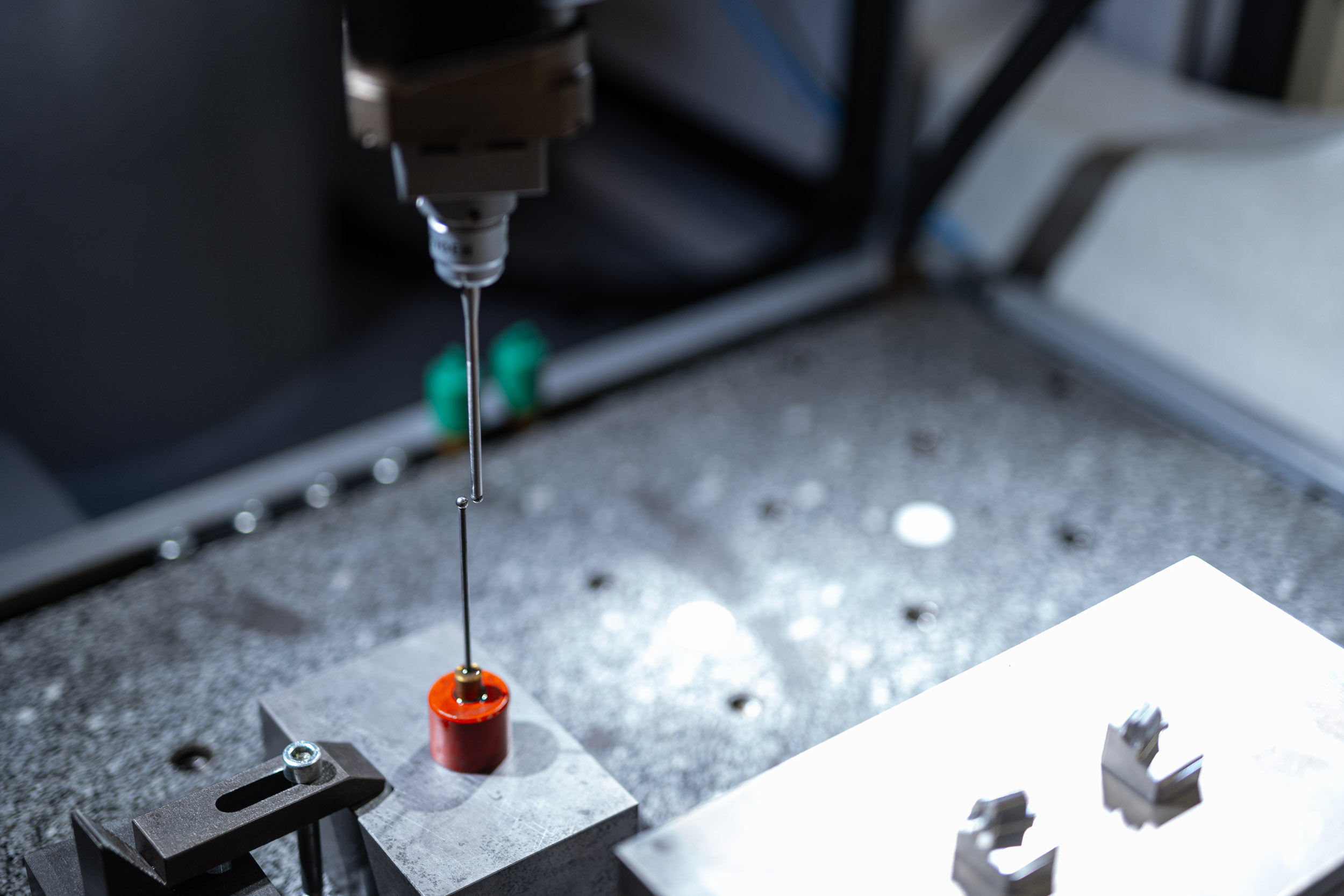

MSA (Measurement System Analysis) is an analytical assessment of the accuracy and reliability of measuring fixtures, in other words, proof of their capability and functionality. Through MSA, we release fixtures into production and also provide their detailed setup using calibration.

Verifying the measuring fixture through various levels of MSA standards assures that the fixture will reliably measure critical product parameters, thereby reducing the risk of production errors.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | CookieYes sets this cookie to store the user consent for the cookies in the category "Advertisement". |

| cookielawinfo-checkbox-analytics | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Analytics” category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by the GDPR Cookie Consent plugin to record the user consent for the cookies in the category “Functional”. |

| cookielawinfo-checkbox-necessary | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Necessary” category. |

| cookielawinfo-checkbox-others | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Others”. |

| cookielawinfo-checkbox-performance | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Performance”. |

| CookieLawInfoConsent | 1 year | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | The website's WordPress theme uses this cookie. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| wpEmojiSettingsSupports | session | WordPress sets this cookie when a user interacts with emojis on a WordPress site. It helps determine if the user's browser can display emojis properly. |

| Cookie | Duration | Description |

|---|---|---|

| wp-wpml_current_language | session | WordPress multilingual plugin sets this cookie to store the current language/language settings. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |