Every mold or product has its own story. To write it with a successful conclusion, we need initial information. We will thoroughly analyze the documentation and all input requirements, communicate them, and mutually decide if we will proceed to further collaboration.

Making a mold is one thing. Another, equally if not more important, is the feasibility study. Feasibility is a crucial step that goes beyond mere mold production. With it, we determine if we can turn requirements into reality. Thus, whether the mold allows for the smooth extraction of the part or product determines its parameters and ultimate functionality.

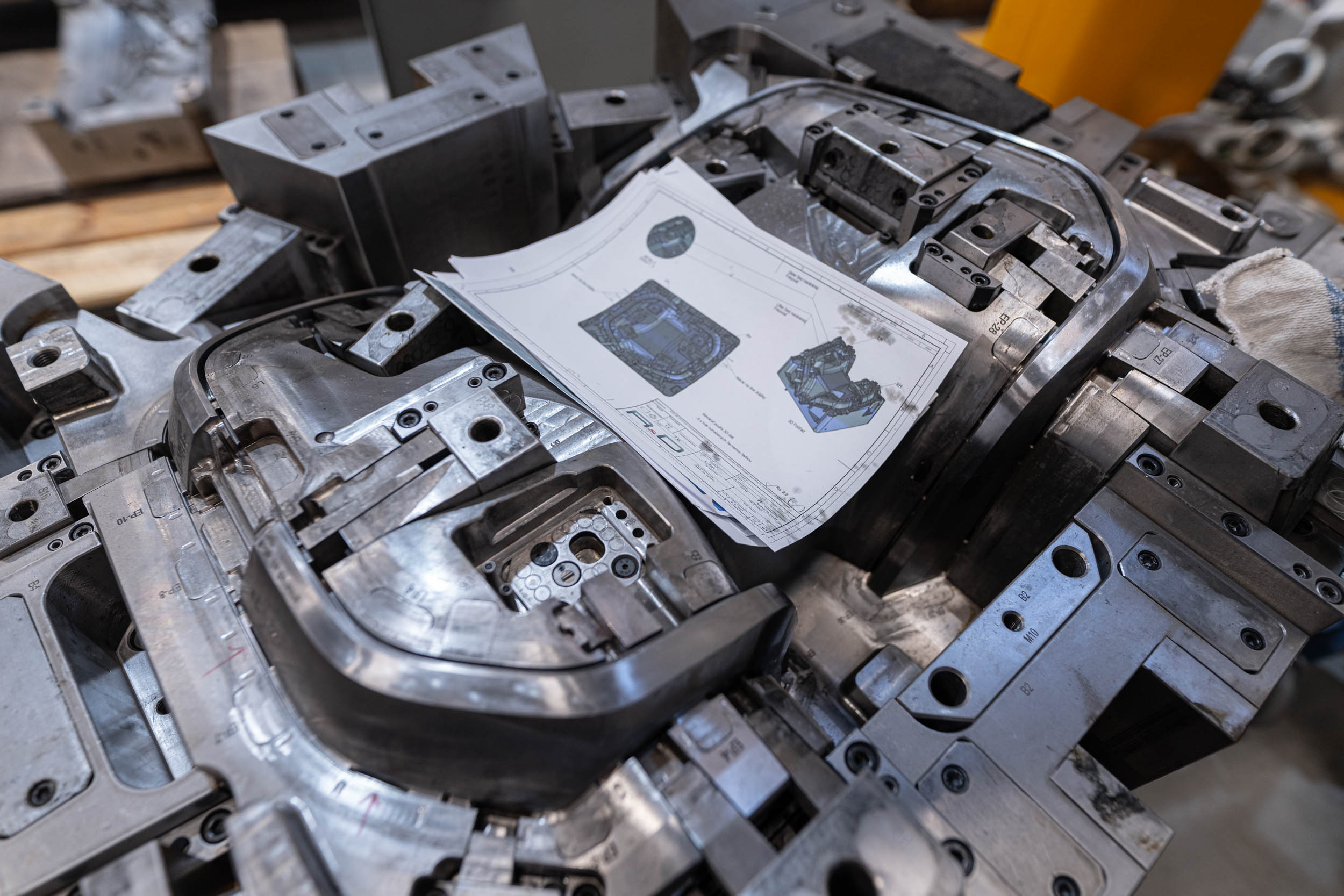

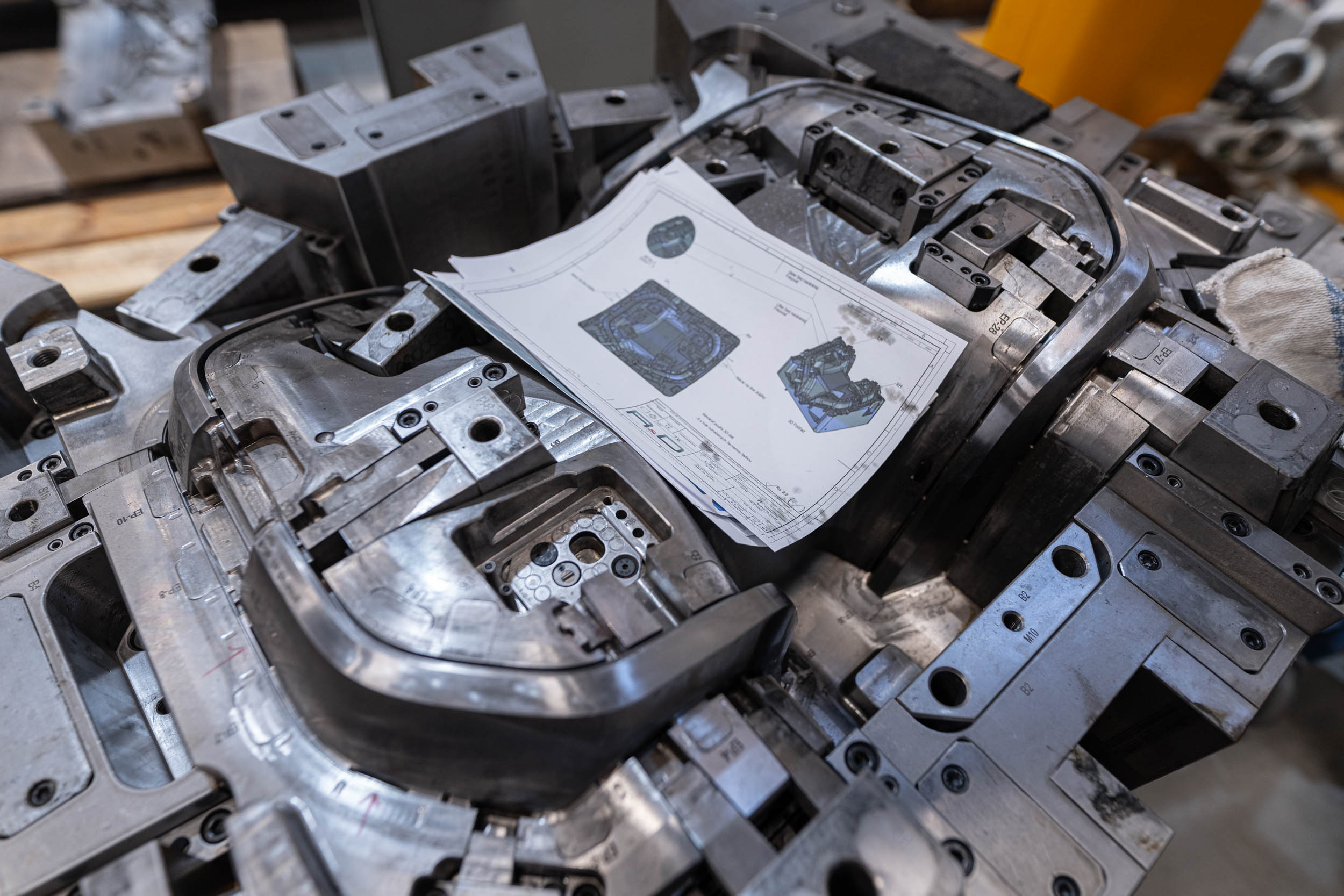

The mold design is again a unique result of the work of our engineering teams. Thanks to their expertise and experience, we can recommend solutions that save you time and costs during production. For verification, we can quickly produce a prototype mold or provide comprehensive services for composite production (from molding to manufacturing the parts themselves). We communicate every critical point with you with an eye toward efficient solutions with the most suitable processes.

The production capacities and technologies we use for mold and engineering product production are among the best in Slovakia. The latest machine equipment, efficient production processes, and know-how ensure we bring every project to a successful conclusion. Part of the production process includes verifying product parameters in our measuring center. We can even easily create unique measuring fixtures for repeated measurements of parts directly in production, ensuring control of the required product parameters.

The product itself – whether a mold or a fixture – is not all you receive at the end of the project. We go a step further. We’ll detail how to use the mold or fixture to facilitate your subsequent production. The methodology eliminates potential production issues or the need for numerous unnecessary trial outputs.

Even after our collaboration ends, our doors are always open to you. For instance, if you need to adjust the mold further or address its maintenance due to wear. The same applies in the event of unexpected problems with mold damage, where our teams will find the fastest way to repair the mold and try to find a replacement solution that won’t completely halt your production.

We can ensure the production of prototype molds according to your requirements, for example, small-scale production, intermediate part production, pilot trial mold production, or verification of product parameters.

Our specialty is producing molds for composites. In a comprehensive range, we can cover the related services for carbon part mold production, sample creation from the mold, and even final production in cooperation with the R&D COMPOSITE division.

We provide production and related services for a wide range of products. Examples include tools, components and parts, devices, spare parts, robotics, or parts for the automotive and other industries.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | CookieYes sets this cookie to store the user consent for the cookies in the category "Advertisement". |

| cookielawinfo-checkbox-analytics | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Analytics” category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by the GDPR Cookie Consent plugin to record the user consent for the cookies in the category “Functional”. |

| cookielawinfo-checkbox-necessary | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Necessary” category. |

| cookielawinfo-checkbox-others | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Others”. |

| cookielawinfo-checkbox-performance | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Performance”. |

| CookieLawInfoConsent | 1 year | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | The website's WordPress theme uses this cookie. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| wpEmojiSettingsSupports | session | WordPress sets this cookie when a user interacts with emojis on a WordPress site. It helps determine if the user's browser can display emojis properly. |

| Cookie | Duration | Description |

|---|---|---|

| wp-wpml_current_language | session | WordPress multilingual plugin sets this cookie to store the current language/language settings. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |